Maintaining a secure and uninterrupted cold chain is essential in 2025. It’s no longer just a recommendation; it’s a critical requirement.

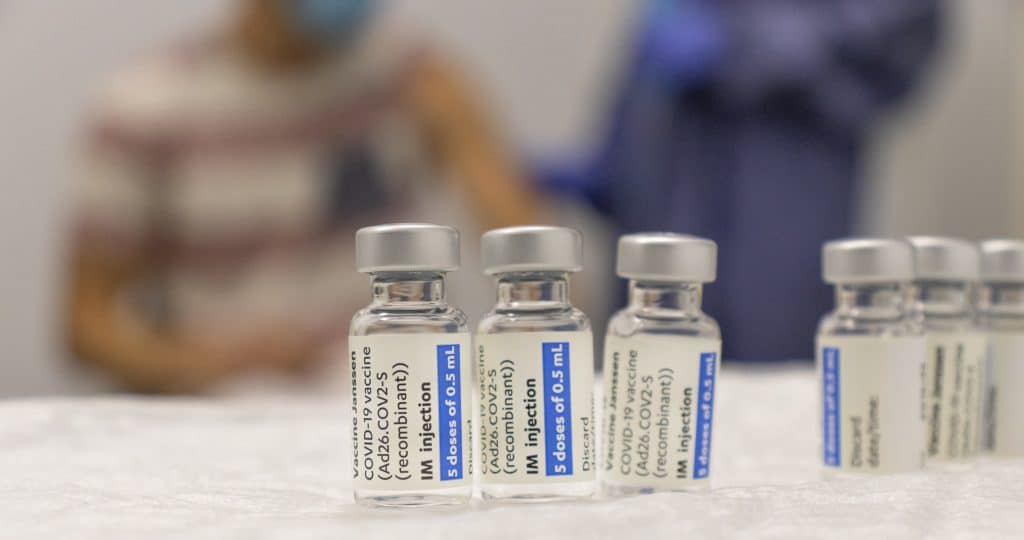

With more temperature-sensitive biologics, vaccines, and advanced therapies, pharmaceutical manufacturers, research labs, and distributors face immense pressure. They must comply with increasingly strict regulations.

At EasyLog, we recognise the complexity of cold chain management. That’s why we offer a complete portfolio of temperature monitoring solutions. From precision data loggers to validated medical refrigeration, designed to protect your products and support full compliance at every stage of the supply chain.

Understanding Cold Chain Compliance

Cold chain compliance refers to the consistent application of regulations and standards designed to keep temperature-sensitive products within defined temperature thresholds during storage and transportation.

Cold chain compliance is crucial. It prevents fluctuations that could degrade or contaminate medicines and vaccines. This ensures product integrity and protects patient safety. For companies, it helps avoid costly spoilage, recalls, or regulatory penalties. Even minor temperature deviations can make some products ineffective or unsafe.

Why Cold Chain Compliance Matters More Than Ever

The pharmaceutical cold chain sector is rapidly expanding, with forecasts estimating its value will exceed $65 billion in 2025 and reach over $130 billion by 2034. This growth reflects rising demand for biologics, vaccines, and advanced treatments like gene and cell therapies. All of which are highly sensitive to temperature changes.

Even brief exposure to improper conditions can compromise these products. In response, global regulatory bodies such as the FDA, EMA, and national authorities are tightening Good Distribution Practices (GDP) and other compliance expectations.

Core Cold Chain Requirements

Meeting compliance standards requires a comprehensive approach built on the following key elements:

- Accurate Temperature Maintenance

Keep products within tightly controlled ranges (e.g. 2°C to 8°C for refrigeration, -20°C for standard freezing, -70°C or lower for ultra-low storage).

- 24/7 Monitoring

Deploy automated data loggers and real-time systems to track temperatures continuously during storage and transportation.

- Validated Infrastructure

Use certified equipment: refrigeration units, transport containers, and monitoring tools that consistently perform to required standards.

- Secure Storage Environments

Ensure proper environmental controls, restricted access, and segregated storage as needed.

- Specialist Packaging

Leverage thermal packaging such as insulated shippers, PCM materials, or gel packs to maintain temperatures during transit.

- Detailed Record-Keeping

Maintain documentation for temperature logs, device calibration, training, and any deviations or corrective actions.

- Contingency Plans

Prepare for incidents with protocols covering power loss, equipment failure and temperature excursions.

- Trained Staff

Ensure all personnel are properly trained in cold chain handling, monitoring and emergency response.

Regulatory Frameworks for Cold Chain

Cold chain compliance is governed by a number of key regulatory frameworks that life science professionals must understand and implement:

- Good Distribution Practices (GDP)

These international standards cover every aspect of product distribution, with an emphasis on temperature control, validated systems, traceability, and trained personnel.

- NIST & UKAS Calibration

Calibration to recognised standards like NIST (U.S.) or UKAS (UK) ensures measurement accuracy and is a critical requirement for compliance.

- EU GMP Annex 11 & Data Integrity Guidelines

These outline requirements for electronic systems in GMP-regulated settings, including validation, audit trails, secure access, and reliable data handling.

- EU Clinical Trials Regulation (EU) No 536/2014

Governs how investigational medicinal products are managed during trials, including temperature control and documentation.

- Country-Specific Rules

Local authorities like the UK MHRA and U.S. Pharmacopeia offer additional guidance and requirements based on jurisdiction.

What is a Cold Chain Breach?

A cold chain breach, also known as a temperature excursion, occurs when a product strays from its designated temperature range during storage or transit. This can include:

- Excess Heat: Exposure to higher-than-allowed temperatures

- Excess Cold: Freezing a product that shouldn’t be frozen

- Time: Duration outside the acceptable range – even short periods can be critical

Common causes include open refrigerator doors, failed refrigeration units, long unloading times, or power outages. For many vaccines, going outside the +2°C to +8°C window (even briefly) can invalidate an entire batch.

The Six Principles of Effective Cold Chain Management

A reliable cold chain is built on these guiding principles:

- Temperature Control & Stability

Maintain stable conditions from production to administration, using appropriate storage, transport, and packaging solutions.

- Continuous Monitoring

Use real-time data and alert systems to ensure immediate response to any deviations.

- Traceable Documentation

Maintain full records of temperature data, handling, and any deviations to demonstrate compliance.

- Proactive Risk Management

Identify potential vulnerabilities and have action plans ready to mitigate disruptions.

- Staff Competency

Ensure everyone handling sensitive products is well-trained and understands the specific handling protocols.

- Validated Equipment & Processes

Use validated tools and procedures that are tested and proven to meet regulatory standards.

The Consequences of Cold Chain Failure

A broken cold chain can lead to serious outcomes, including:

- Product Degradation

Temperature-sensitive medicines lose their therapeutic value or become unsafe.

- Public Health Risks

Ineffective vaccines and drugs put patient health in jeopardy.

- Financial Losses

Damaged products, restocking costs, and halted distribution can cost millions.

- Regulatory Action

Breaches may trigger audits, fines, license suspension, or product recalls.

- Reputational Damage

Trust and brand image suffer after compliance failures.

- Supply Disruptions

Breaches can cause critical shortages and interrupt treatment availability.

- Environmental Waste

Spoilt pharmaceuticals contribute to medical waste and environmental impact.

EasyLog: Supporting Compliance with Confidence

EasyLog delivers advanced solutions tailored to the needs of the pharmaceutical and life sciences sector.

Our data loggers are more than just temperature trackers, they’re precision-calibrated instruments designed for regulatory environments. They support real-time alerts via SMS, email, or visual signals, and connect to the EasyLog Cloud, enabling you to monitor and manage your cold chain from anywhere.

EasyLog Cloud offers:

- Secure digital records with long-term cloud storage

- Full audit trails (user actions, device events, exports, etc.)

- Electronic signatures for 21 CFR-compliant recordkeeping

- User access control with role-based permissions

- Customisable reports for audits, validation, and analysis

- Onboard memory in devices for local data logging

- Support for multiple external probes

- Glycol-filled probe options to simulate product temperature

- Real-time monitoring with email, SMS, and visual alerts

- Cloud connectivity for remote access and visibility

Ready to protect your cold chain?

Explore EasyLog’s range of professional-grade monitoring tools, medical fridges and freezers. All designed for life sciences and built for the future.